Western Managed Manufacturer - World Class Design and Production

Services | Solutions | Products | Who Are We | Contact Us

Die Cast Aluminum Products

Powder Coated Black

Home /

Insert Molding, Over Molding, and Rapid Prototypes

/

Plastics

We have both experience

and proficiency in the following manufacturing practices with regard to

plastics. Our capabilities include the ability to do

Injection Molding, Insert

Molding, Over Molding, Blow Molding as well as Extrusion. Read further

to understand the differences in each type or contact us and we will be

happy to discuss which is right for your product.

What plastic is right for me?

We will analyze

your product for the required physical and mechanical properties to choose

an accurate material for your product. Common requirements often

include high strength, temperature resistance, weather resistance, or extra

high precision.

We have experience

with regards to plastic product manufacturing in materials ranging from common

resins to engineered resins (fairly exotic). We have previously manufactured using

plastics from the families of PP, PE, PVC, ABS, AS (SAN), Acetyl, Nylon,

to name just a few. We use materials from world class manufacturers like Dupont,

LG, BASF, Sinopec, Ciba and so on or the lower end depending on what

kind of budget you have for your product and the requirements of the product. Some specialized injection

molded plastic parts may require reinforcement with glass or carbon fibers

imbedded in the resin.

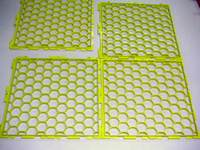

Our experts in plastic coloration can choose pigments to give your product

the desired color. We custom match the color required and have a

master batch created so that all products are consistently the same color

throughout the life of the product. Often, ultraviolet inhibitors can be added to

protect the product against color fading as well as protecting for a weakening of strength

from sunlight. Click here to read more about

injection molding.

Insert Molding

Insert molding is a process which uses injection molding to join separate

parts together into a single component. Basically, a second object

which is metal, plastic or other,

is inserted into a custom-designed injection mold. After the injection

molding cycle, the 2nd piece is permanent embedded into the product.

As the 2nd piece is inserted into a mold, what you get is a

high-quality product

which is durable and always aligned perfectly.

Why use insert molding?

When not using

insert molding, the assembly/connection of discrete parts through fasteners,

connectors, soldering or adhesives is labor-intensive, costly and not as

secure. In addition to greater efficiency, insert molding offers many

other benefits.

Using a method whereby you connect 2 parts together, you will need to use a

form of connector which adds weight, will not be as durable for the

short-term or for long term. As the connector itself is plastic of the

product, you eliminate the connector, thereby reducing the cost as well as

the weight of the connector.

No matter whether we use insert molding or assemble pieces using other

methods, we combine manual

and automated techniques to ensure optimum results in all of our products.

|

|

|

|

Insert Molded Brass Bushings |

Insert Molded Fitting |

|

|

|

|

|

Insert Molding a High Tensile Strength Pultruded Rod |

||

Over Molding

Over molding is a

process that allows

for two different molds to be used to injection mold the same part in order

to improve appearance or

durability. A good example is over molding a rubber handle/grip over a

product.

It is also commonly used when a combination of inserts is too complex to be

completed by one molding process. The most common applications of over molding

are so that

the product has a more comfortable and better grip,

insulate electrical components, make parts water resistance or reduce

vibration during product use.

|

|

|

Over Molding a Rubber Handle |

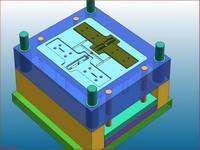

Rapid Prototyping

Rapid Prototyping/Model Making is often a crucial step during the product

design and development cycle.

It is very useful in checking form, function and appearance before spending

large amounts of time and money the production mold. Often, 2D and 3D

drawings and sketches are very valuable in determining dimensions and

general form, but sometimes critical ergonomic and atheistic features aren't

noticeable until you can see and feel an actual size product. We

provide high-quality,

high-precision prototypes for your consideration.

Using prototypes reduces the risk to you, allowing you to test

the market by showing off an actual sample for comments and feedback before investing in any expensive

production tooling.

|

||

|

Rapid Prototype Manufacturing |

|

Our Expertise Includes:

Manufacturing

|