Western Managed Manufacturer - World Class Design and Production

Services | Solutions | Products | Who Are We | Contact Us

Manufacturing • Sourcing • Quality Control • CAD/3D Drawing • Testing

Home / Solutions / Manufacturing

Manufacturing

We are a manufacturer with both experience and expertise in a wide range of production methods. Manufacturing with us is an effective and rapid way to increase quality, increase production speed and decrease costs for all components as well as the finished product. This allows you to re-allocate your resources to other crucial areas of your business such as sales and distribution. Read more about us in who we are.

Design

Using our extensive manufacturing knowledge we review your designs and concepts and work with you to optimize the design for quality, cost-effectiveness, strength and ease of manufacturing. Whether beginning a new concept product or economizing an existing design, we can work with you in order to analyze and find the best solution that meets your design and product requirements.

Starting the project, we research and choose the appropriate raw materials for your products, conferring with you to confirm the required physical, atheistic and mechanical properties. Once ready, we allocate production space and time for the project and write up and follow a strict internal WIP (work-in-process) control to ensure quality and speed during production. After the finish of production, we package the goods and ship them out as per your requirements. We handle all outgoing local freight, customs, tariffs, port duties as well as arrange for the shipment. Read more about our quality control measures or about our in-house testing.

Important Components of Every Project

![]() Product Design

Product Design

![]() Tooling Design

Tooling Design

![]() Cost Savings

Cost Savings

We incorporate these three elements using our in-depth background of manufacturing and engineering to make sure your product meets the requirements of Form, Fit and Function. These help insure success for all projects we do.

|

|

|

|

Various Projects Finished and Ready for Shipment | ||

Expertise

In addition to our manufacturing capabilities, we have expertise and offer full product engineering services ranging from design and development to reverse and value engineering.

Though all manufacturing uses a lot of expensive capital equipment, labor and mold/die costs are still the most costly components of production costs. Our main cost advantage comes from savings in this area. Wages for workers and tooling are among the lowest in the world, and we utilize these to pass along savings to you.

A further advantage that we have is that many Western manufacturers have high factory overhead costs. This is partly the result of those factories operating at less than full capacity because of weak business conditions and intense foreign competition. We operate 24 hours a day, 7 days a week, more fully utilizing our machinery and making it relatively less costly taking into account the power saving schedules.

Capabilities

We manufacture and assemble all goods in our own factory which is located in Northern China. On the right are just a handful of the engineering and mechanical processes that we utilize in our factory. Click on any of them to see more detailed page regarding those processes.

Contact us at Info@3CInterglobal.com for a quotation on your product.

|

Our Expertise Includes: Manufacturing

|

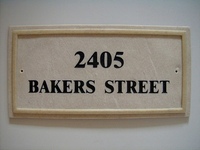

Insert Molding of a Rod made

from Pultrusion with a

Custom Logo Wrapping